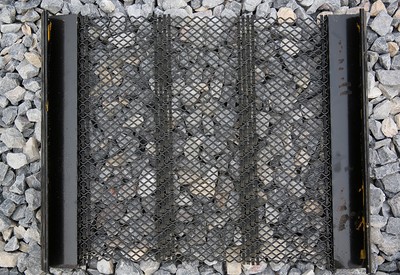

Self-cleaning screen is a specific type of screening media made with multiple individual metal wires or polyurethane material. Independent vibration of the wires is created at variable frequencies to provide a good self-screening effect without plugging the meshes.

Screening Media

Based on “Zero Defect” principle in production, Red Star rigorously implements ISO quality management system. From the procurement of raw materials through to the delivery of finished article, our rigid quality control and tracking system is maintained at every stage of manufacturing to ensure the production of consistent quality products.

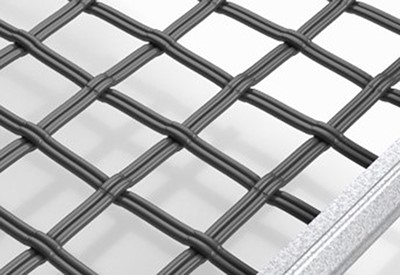

Woven wire screen is the most common type of screening media used in aggregate processing and mining applications due to its features of high open area, high weave precision and high cost-performance ratio.

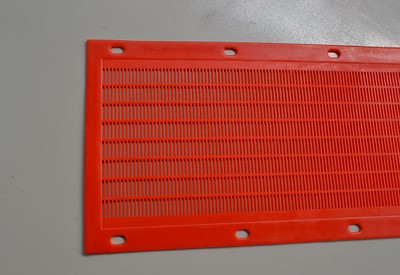

Red Star’s polyurethane screens are manufactured using open-cast process which provides wear life of 1.5 to 2 times longer than that found in injection-molded polyurethane screen. Although open-cast production method is more labor-intensive, but it results in superior wear life performance and minimal maintenance cost, primarily due to the long slow curing process which enhances the cross-linking of the polyurethane molecules.

Red Star’s polyurethane screens are manufactured using open-cast process which provides wear life of 1.5 to 2 times longer than that found in injection-molded polyurethane screen.

Perforated plate screen is primarily designed for high-impact applications on top screen decks. This screen can be custom manufactured to your own demands of screen thickness, opening size, shape and layout. A variety of materials is available to meet actual application needs.

Red Star stainless steel screen mesh is a type of replacement screens for the majority of shale shakers. Our available materials include 304, 316 and 316L stainless steel.

In addition to providing an array of high quality screening media, Red Star can also supply custom designed screening accessories to suit the specific requirements of our customers.

Our team of seasoned engineers is capable enough of providing customers with screening solutions tailored to their individual applications. In addition to our thousands of existing molds, we also have strong mold designing and molding capabilities to efficiently turn every our customer’s design into quality guaranteed screening products.

Red Star’s a broad range of products includes woven wire screen, self-cleaning screen, polyurethane screen, wedge wire screen, perforated plate screen and stainless steel screen mesh, which are applicable to an extensive variety of industries including aggregate processing, non-metal and metal mining, asphalt mixing, waste recycling, coal, construction, industrial, agricultural, petroleum, etc.