Polyurethane Screens

Red Star’s polyurethane screens are manufactured using open-cast process which provides wear life of 1.5 to 2 times longer than that found in injection-molded polyurethane screen. Although open-cast production method is more labor-intensive, but it results in superior wear life performance and minimal maintenance cost, primarily due to the long slow curing process which enhances the cross-linking of the polyurethane molecules.

Applications

Polyurethane screens can perform effective screening in the majority of wet and dry applications.

All raw materials and manufacturing equipment for Red Star’s polyurethane screens are sourced from Europe, and our quality control is certified in accordance with ISO quality management system, allowing us to provide consistent top quality polyurethane screening products.

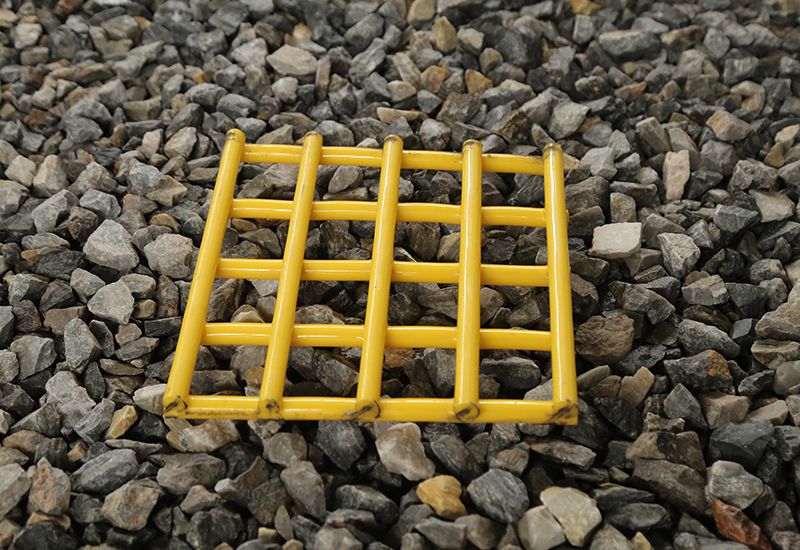

Polyurethane tensioned screen is an optimal alternative to woven wire screens. The assembly of polyurethane tensioned screen can be easily carried out without any modifications to the screening machine structure, directly in place of woven wire screen. Our polyurethane tensioned screen is steel cable reinforced to increase its resistance to strain and load, while prolonging the wear life. Customization of polyurethane tensioned screens is available to accommodate your existing screening machine brands.

-

Specifications

- Opening size

- 25.4-152.4mm

- Thickness

- 10-90mm

- Screen size

- Max.3m width

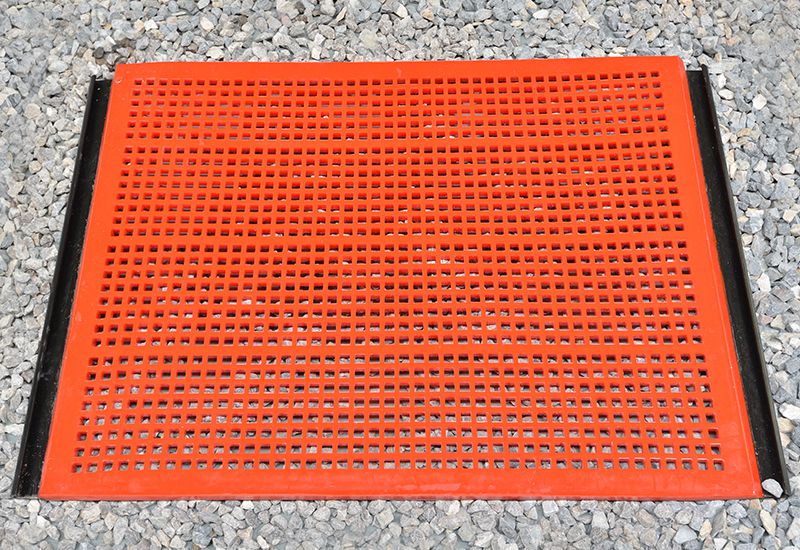

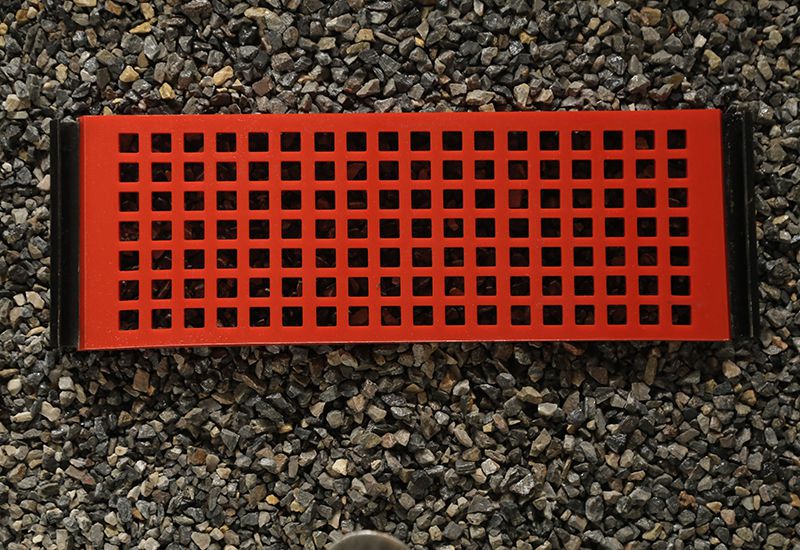

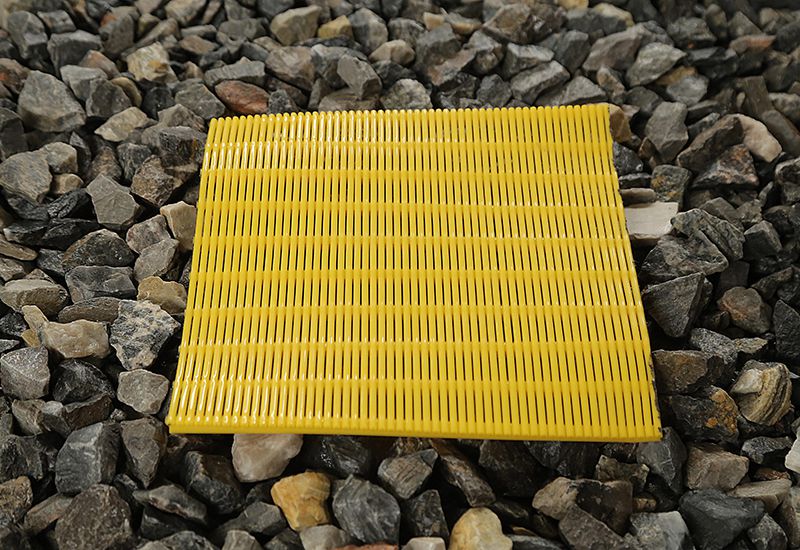

Red Star manufactures polyurethane screen panel available with solutions tailored to customer’s application needs in relation to wear life, color, bolting method, etc.

-

Specifications

- Opening size

- 0.3-152mm

- Thickness

- 20-75mm

- Screen size

- 60-90 shore A

Polyurethane screen panel is widely used as vibrating screen mesh for fine screening of coal, minerals, coke, beans and more bulk materials in agriculture, chemical, mineral, quarry, smelting and many other industries.

Since the polyurethane screen panel can perform screening and classifying of wet fine materials, it can also be used in water conservation, hydropower and dewatering industries.

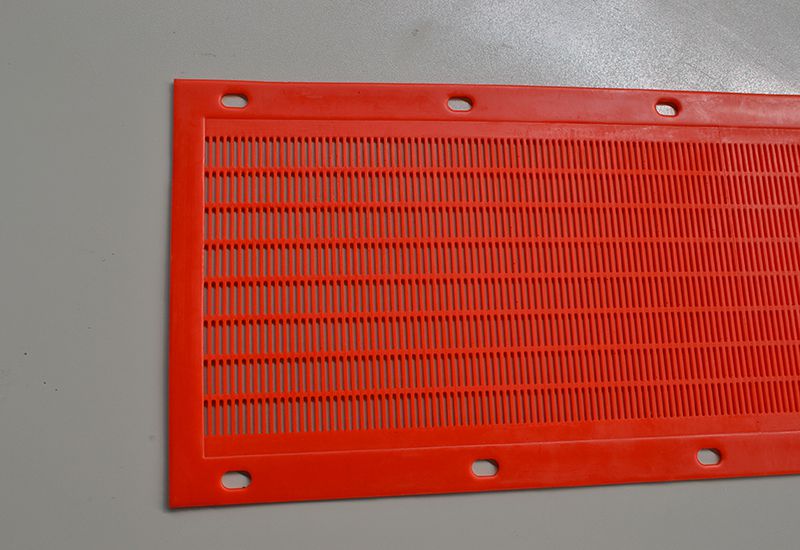

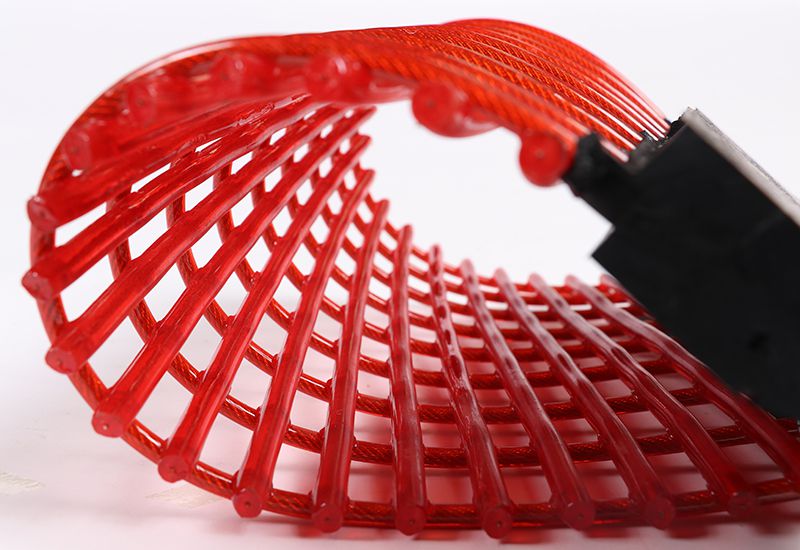

Flip flow screen or flip flop screen is a type of PU screening media suited to efficiently screen dry, sticky, wet and other difficult materials. The large open area promotes the flow of materials while preventing blinding and clogging of the screen surface. Red Star can offer custom-made flip flow screen with different options of hardness, thickness, aperture opening size, shape and layout, no matter whether it is deployed in dry screening or wet screening applications.

-

Specifications

- Opening size

- 3×11-50×100mm

- Thickness

- 6-15mm

- Screen size

- 305mm width or customize

Flexible Polyurethane Screen has a larger open area compared to conventional woven wire screen, with a long wear life of 3-8 times that of steel wire screen. Through the double vibration principle that both screening machine and screen mesh are vibrating, the mesh openings are less prone to blinding, clogging and pegging. Lightweight and easy installation can greatly reduce labor intensity and machine downtime.

-

Specifications

- Opening size

- 1.5-45mm

- Thickness

- 1.2-12mm

- Screen size

- Max.3m width

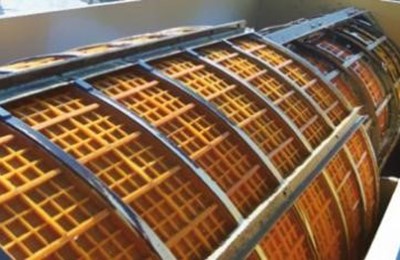

Red Star’s polyurethane fine screens are applicable to well-known screening machines for replacement of their wire meshes and polyurethane screens, which are commonly found in iron powder screening applications. Our polyurethane fine screens are supplied in minimum aperture size of 0.063mm, can deliver the highest level of screening efficiency and wear life. A range of specification options is available to meet customer’s individual screening needs.

-

Specifications

- Opening size

- 0.063-1.5mm

- Screen size

- 1045X700mm, 840X1245mm, 1000X2320mm, 1200X2320mm