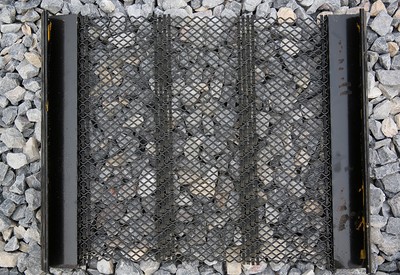

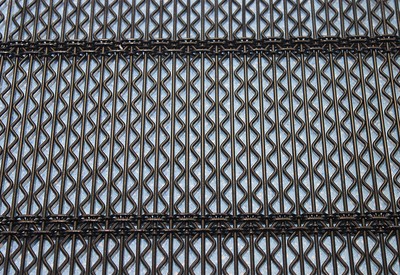

Self-Cleaning Screen (Woven Wire Cloth)

Self-cleaning screen made of woven wire cloth has an advantage of higher temperature resistance which polyurethane self-cleaning screen can not replace, it is typically used in sectors of road construction or asphalt mixing. The individual steel wires vibrate independently helping to avoid clogging or plugging while improving screen efficiency. This type of self-cleaning screen is generally applied in most common screening applications.

Woven wire screen having triangular openings features larger load bearing capacity, less deformation and higher screening accuracy in contrast to screens with diamond shaped openings.

-

Specifications

- Opening sizes

- 2.0mm-45mm

- Materials available

- patented wire (65mn manganese steel wire), stainless steel, medium carbon steel, high carbon steel

- Wire

- >0.8mm

- Screen size

- Max. 3m width

Applications

- Sand and gravel industry

- Ore preparation plants

- Mining industry

- For wet, sticky, hard-to-screen materials

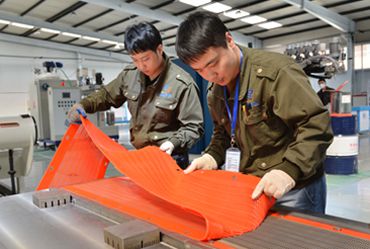

In-House Production

Other Self-cleaning Screens

Red Star has been supplying high quality screening surfaces to aggregate processing, recycling screening, quarrying and mining industries since its foundation in 1989. Today, we specialize in the design and manufacture of industrial screening media with tailor-made screening solution for customer’s specific needs. We are able to offer braided wire meshes, or plastic screen meshes such as polyurethane screen panels and screening accessories. Whether you are a screening equipment manufacturer looking for qualified wire meshes for your product or an end user looking for replacement screens to refurbish your older existing screening and classification equipment, Red Star can get the job done efficiently.