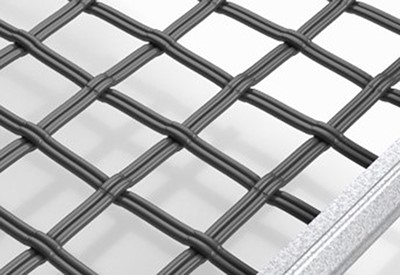

Woven Wire Screens

Woven wire screen is the most common type of screening media used in aggregate processing and mining applications due to its features of high open area, high weave precision and high cost-performance ratio.

Aperture tolerance only ±3% is far superior to the industry standards in domestic and global markets, which can lead to high-precision screening and guaranteeing the percentage of material qualification. The high quality materials can yield a higher profit for manufacturers.

Features

- Red Star patented metal wires are all subjected to heat treatment process to increase the ductility, hardness (wear resistance) and tensile strength, allowing the wire to be stretched without tearing and breaking in high impact conditions.

- Our woven wire screen is characterized by greater abrasion resistance, better overall performance and 40% prolonged wear life in contrast to conventional screen mesh, significantly reducing downtime and replacement costs.

- Thanks to the advantageous qualities of our patented metal wires, it is expediently to use a smaller diameter wire to have a larger open area for increased throughput, without compromising on wear resistance and lifespan.

Materials

Red Star patented metal wire is skillfully manufactured through all steps from very beginning of chemical formulation to heat treatment process, aiming at providing the best combination of ductility, hardness and tensile strength, enabling our woven wire screen to be more resistant to abrasion and less susceptible to breaking. Along with that, Red Star offers a full array of metal wires to solve customers’ individual screening demands, no matter how simple or complex your application is. Our common materials used to create woven wire screen are high carbon steel, medium carbon steel (particularly suitable for architectural screens), stainless steel (304/316/316L/S340…), copper and more metal wires to meet customer’s specific needs.