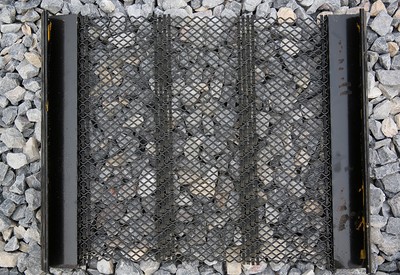

Self-Cleaning Screen (Modular Screen Panel)

Unlike conventional tensioned wire mesh that requires more machine downtime due to replacement of screens, the modular design of the self-cleaning screen helps significantly and efficiently boosting productivity while reducing machine downtime. Red Star can offer several installation methods to accommodate customer’s individual demands. Opening sizes are available in a range of 2.03-152.4mm.

-

Specifications

- Opening sizes

- 2.03 mm-152.4mm

- Screen size

- 1’×2’, 2’×2’, 1’×4’

- Materials available

- patented wire (65mn manganese steel wire), stainless steel, medium carbon steel, high carbon steel

- Wire

- >0.8mm

Applications

- Sand and gravel industry

- Ore preparation plants

- Mining industry

- For wet, sticky, hard-to-screen materials

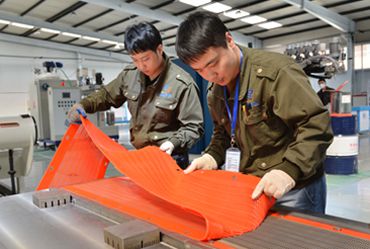

In-House Production

Other Self-cleaning Screens

Red Star has been supplying high quality screening surfaces to aggregate processing, recycling screening, quarrying and mining industries since its foundation in 1989. Today, we specialize in the design and manufacture of industrial screening media with tailor-made screening solution for customer’s specific needs. We are able to offer braided wire meshes, or plastic screen meshes such as polyurethane screen panels and screening accessories. Whether you are a screening equipment manufacturer looking for qualified wire meshes for your product or an end user looking for replacement screens to refurbish your older existing screening and classification equipment, Red Star can get the job done efficiently.